Third generation

Semiconductor Testing

family

Third generation semiconductor testing family

MENU

- CO2 series laser marking machine

-

Fiber optic series laser marking machine

- Fully automatic IC printing detection system QH-APV5090

- Fully automatic IC lead frame marking system QH-APV100SL

- Fully automatic IC lead frame marking system QH-APV100LF

- Pulse double-head laser marking machine

- 5W/10W/20W continuous fiber laser marking machine

- Video positioning and marking machine

- 10W/20W/30W pulse laser marking machine

- Green/Purple series laser marking machines

- Three axis dynamic laser marking machine

- CO2 series laser marking machine

-

Fiber optic series laser marking machine

- Fully automatic IC printing detection system QH-APV5090

- Fully automatic IC lead frame marking system QH-APV100SL

- Fully automatic IC lead frame marking system QH-APV100LF

- Pulse double-head laser marking machine

- 5W/10W/20W continuous fiber laser marking machine

- Video positioning and marking machine

- 10W/20W/30W pulse laser marking machine

- Green/Purple series laser marking machines

- Three axis dynamic laser marking machine

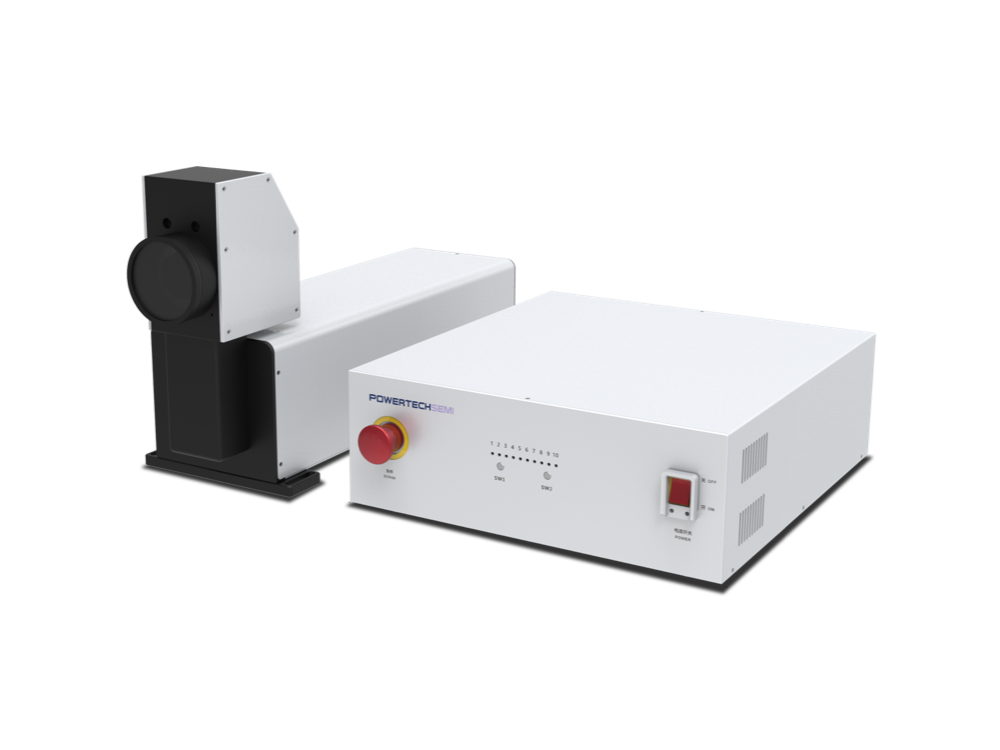

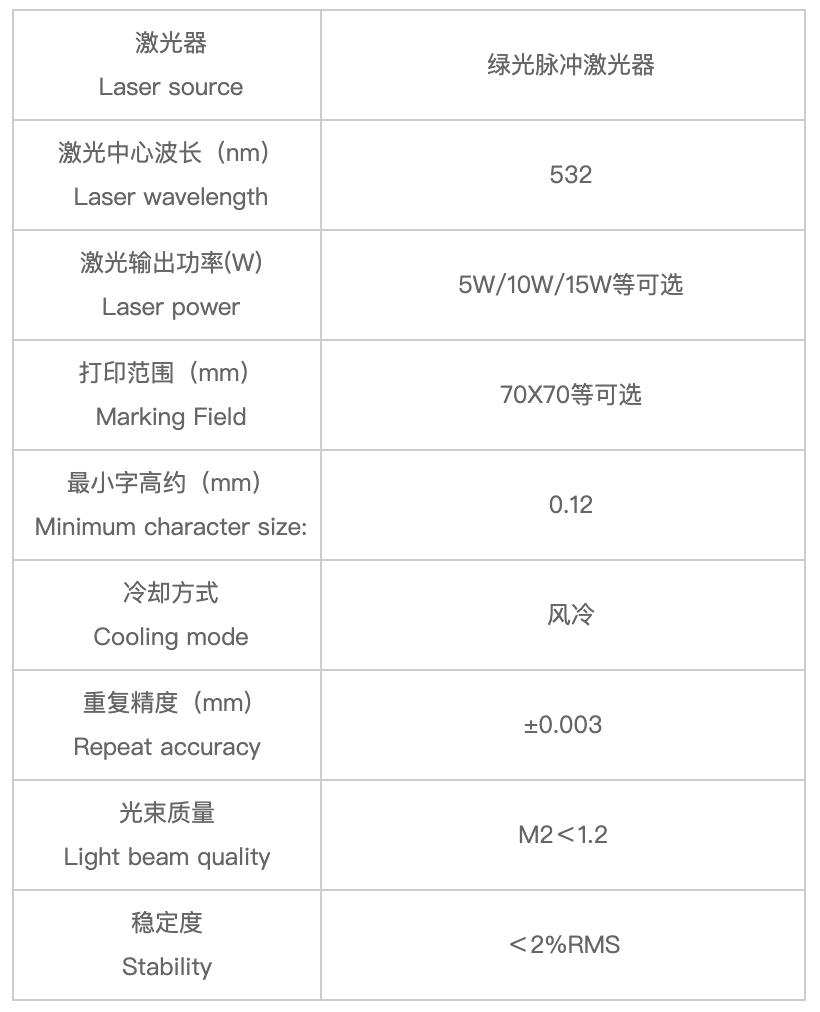

5W/10W/15W pulsed green laser marking machine

The green light laser marking machine adopts international advanced resonant cavity design and laser control technology to achieve excellent beam quality, high long-term working stability, and narrow laser pulse width under high-power operation.

|

High electro-optical conversion efficiency and long service life |

The laser spot output is extremely small and the light pattern is good |

Laser output power is extremely stable |

Cold working concept |

| Type | 5W/10W/15W Pulsed green light laser marking machine |

| Advantages | Power management; digital consumer; audio; automotive, energy-saving and environmentally friendly electronics; special or customized IC and wafer testing. |

| Introduction |

? Laser Marking ? Laser trimming ? Thin film photovoltaic cell manufacturing ? Micromachining ? PCB, FCP depaneling, cutting and drilling ? Ceramic and silicon wafer scribing ? Wafer product marking and cutting ? LED sapphire substrate substrate ? Material engraving and cutting of PVC and ABS ? IC devices, plastic metal frame engraving |

Testing standards

Recommended products

|

|

No. 16 Guangming Avenue, New Light Source Industry Base, Nanhai National High tech Zone, Foshan City, Guangdong Province, China |

|

|

+86 757 83207313 (Sales) |

|

|

+86 757 83208786 (Sales) |

|

|

info@powertechsemi.com |

Copyright PowerTECH industrial Co., Ltd. Powertechsmemi.com ? 2015 | Privacy policy | Sitmap 粵ICP備17127080號(hào)-1